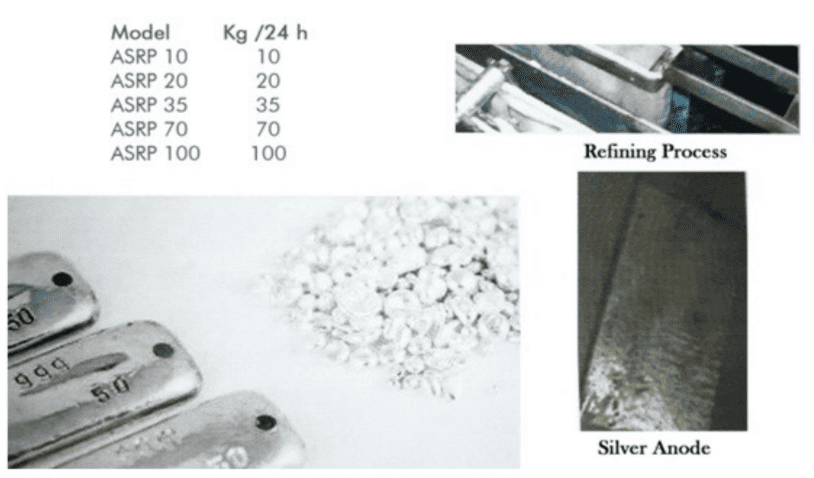

SILVER REFINING

Inquire About It More

SPECIFICATIONS

-

Silver electrolytic refining is currently the most economical and functional process able to ensure 999.0% silver production. Work stages contain 3 steps :

1.Ag containing anode material melting

2.Electrolytic refining

Pure silver fusion obtained according to amount requested by

customer ( grit, ingots, galvanic use anodes etc.)

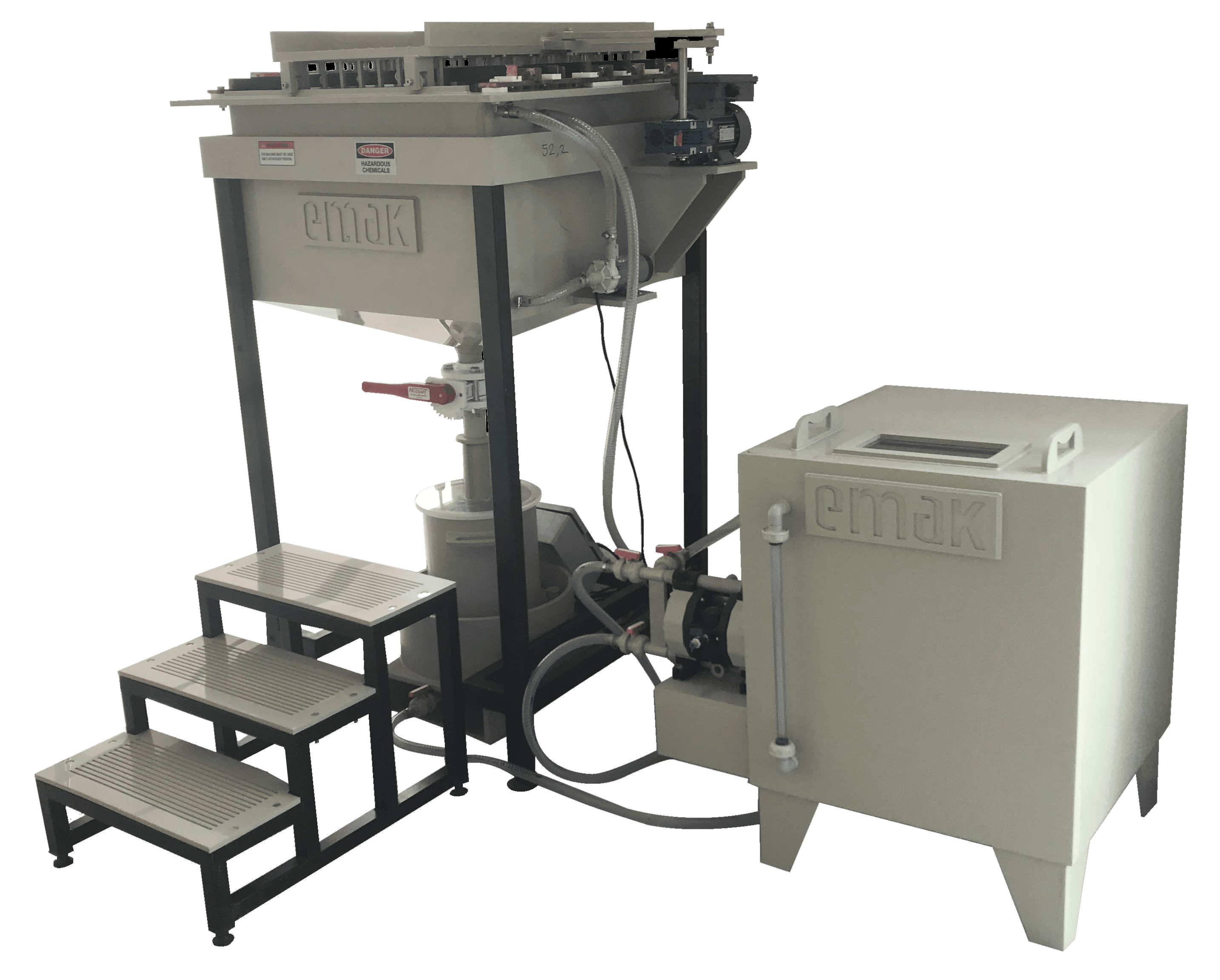

- ASRP 100 refining plant is able to refine up to 100 kg of silver every 24 hours and is equipped with :

-Varnished steel support structure

-n. 3, 100 lt, PPS electrolysis tank, complete with a base truncated

pyramidal cone and discharge valve. The electrolysis tank is

complete with anodic and cathodic copper barrier, 3 Aisi 316

Stainless Steel cathodes.

-n. 03 PPS, 100 I recirculation tank.

-n. 01 titanium anode trays

-n. 03 PPS, Meraklon electrolysis cells

-n. 03 100A, 10V current rectifier

-n. 03 cart equipped with Buchner funnel with Mk filter and ½”

membrane pump

- Technical characteristics

-Power supply : depending on each country’s circumstances

-Power : 5kW

-Overall dimensions (in line) 1500 x 800 h 2400 mm

-Weight : 700 kg