DEBURRING POLISHING MEDIA

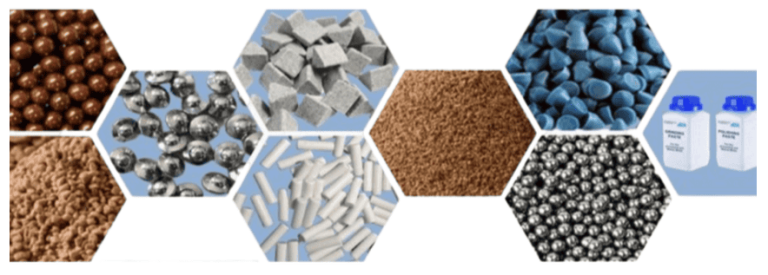

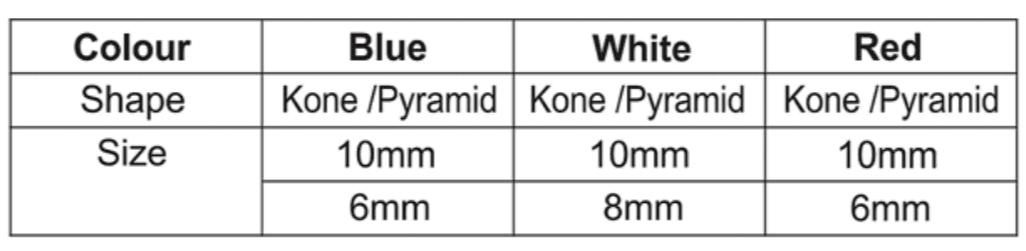

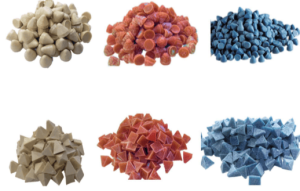

1. PLASTIC ABRASIVE MEDIA

- It is used for smoothing surface of the non ferrous metal such as gold, silver, brass, copper, white metal.

- Available in two shapes cone and pyramid.

- Various grades are available for different application

- A lower density cost effective finishing media, an alternative to conventional media offering qualities & depreciation rates similar to ceramic media.

- High performance Grinding Medium Roughness.

- A low fine finishing media for producing a very flat fine surface on all metals from fine grinding to polishing, specially for the jewelry industry.

Inquire About It More

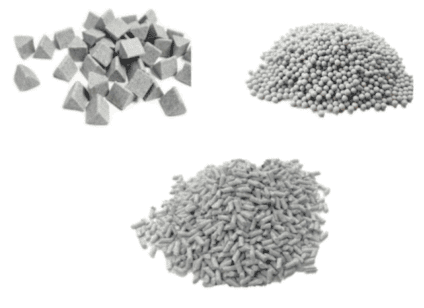

2. CERAMIC ABRASIVE MEDIA

- It is widely used for ferrous metals as well for non ferrous too where highly smoothing is required at less time

- Ceramic media is best for heavy cutting and hard metals.

- Ceramic media supports very heavy parts better that plastic media.

- Ceramic finishing media is the most common media used in mass finishing.

- Its provide high abrasive properties due to which grinding rate is increased

- Ceramic Ball

- Ceramic Angle Cut Cylinder

3. PORCELAIN MEDIA

- It is used for wet polishing and also in circular vibrator for polishing light weight work pieces.

- Available in various shapes and sizes.

- It produces high luster / mirror finish for stainless steel parts, while having low wear rate

- Porcelain Angle Cut

- Porcelain Ball

4. STAINLESS STEEL MEDIA

- It is used for polishing and burnishing.

- It is made up of high grade steel and available 4. STAINLESS STEEL MEDIA in pins, balls, satellite of varying sizes

- Stainless steel pin’s shape is used in magnetic polishing machines only for the shining step, especially when there are internal surface impossible to reach by hand

5. HIGH POLISHING BALLS

- Very hard and long – lasting

- Very High polishing properties

- Highly recommended for use in vibrators and finishing machines sizes available (from 0.7 mm to 3.2 mm)

- Reach Intricate areas also

6. DRY POLISHING MEDIA

- Walnut chips – We have impregnated and nonimpregnated walnut shells for polishing as well as grinding.

- corn cobs, wooden media, crushed walnut shells are extremely durable, angular and multi faceted

7. POLISHING COMPOUND

- 1.Deburring compound

- 2.Polishing Compound

- Polishing media and work piece lubrication

- Reduction in loss of abrasive stones

- Retain surface lustre

- Anti-rust

- Increased efficiency of wet grinding

- Surface oxide softening

- Grease removal

- Clean workplace

8. PASTES

- Grinding paste

- Smoothing paste

- Polishing paste

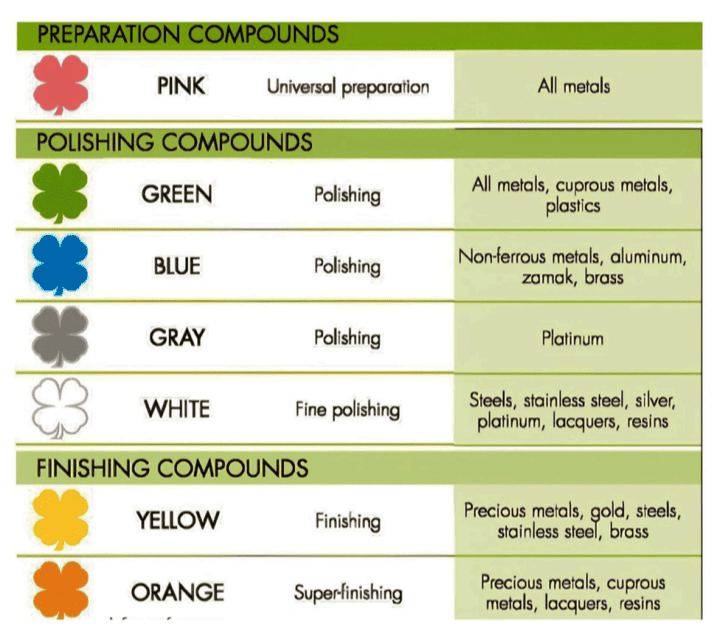

9.LUXOR

- 1.Jewellery | Watchmaking | Eyewear Writing Instruments | Medical Implants

- HIGH PERFORMANCE, MIRROR FINISH

- LESS GREASY, CLEAN WORKING

- BETTER THAN LOCAL TRIPOLI, ROUGE, LUSTRE

- GREATER ABRASIVE CONTENT